bursting strength test of corrugated box|bursting strength calculator : wholesalers Minimum Bursting Test (lbs per sq. inch/kg per sq. cm) Minimum Edge Crush Test (ECT) (lbs per inch/kg per cm width) 5-10* 30* 125 * 23* 30 75 200 32 40 75 200 40 . It’s one thing to understand corrugated box strength in theory and another to see it in action. Before you choose your shipping boxes, order samples with a few different .

Top free NSFW games - itch.io. Games. (15,404 results) Sort by. Popular. New & Popular. Top sellers. Top rated. Most Recent. Erotic. Adult. Romance. Visual Novel. 3D. Anime. .

{plog:ftitle_list}

Hoje, The Good Doctor está em 881 no Ranking Diário de Str.

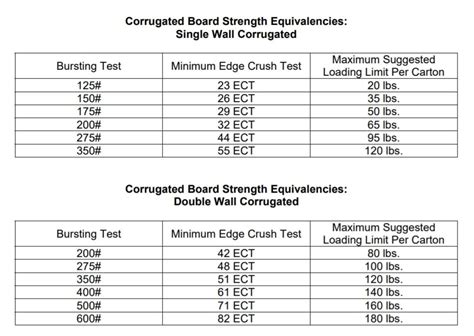

When determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in pounds and is related to the handling durability of the box material. The bursting strength of a corrugated sheet can be easily calculated by performing the bursting strength test or the Mullen test. This is .Below is a chart that breakdowns different types of corrugated material and their corresponding bursting test and ECT rating, along with the maximum load per carton. The 32 ECT, 44 ECT, and 48 ECT are the most common box .Over 42,000 products in stock. 13 Locations across USA, Canada and Mexico for fast delivery of 275 Lb. Test Single Wall Boxes. Enable Accessibility . Boxes, Corrugated > Heavy Duty Boxes > 275 Lb. Test Single Wall Boxes; .

There are a number of different ways to test the bursting strength of a corrugated box, but the most common method is the Mullen test or bursting strength test.This can be performed with the help of the Presto bursting strength tester digital model that comes with feather touch controls and strong gripping clamps to accurately place the machine on the surface. Minimum Bursting Test (lbs per sq. inch/kg per sq. cm) Minimum Edge Crush Test (ECT) (lbs per inch/kg per cm width) 5-10* 30* 125 * 23* 30 75 200 32 40 75 200 40 . It’s one thing to understand corrugated box strength in theory and another to see it in action. Before you choose your shipping boxes, order samples with a few different .

Bursting Strength Tester digital model is a very accurate instrument for the measurement of bursting strength of corrugated boxes and paper by manufacturers and suppliers. It has a two in one feature of calculating bursting factor of both paper and corrugated boxes under one single head. . Test Standards: ASTM D 3786-01, ASTM D 3786 – 80A .Mullen Test (Burst Test) for Box Strength. The Mullen Test (burst test) has been used for over 130 years to determine how resistant a box is to punctures. . Double Wall Corrugated Box ECT/Mullen Conversion Chart; Max. Suggested Load/Box Min. Edge Crush Test Mullen (Burst) Test; 100 lbs. 48 ECT: 275# 120 lbs. 51 ECT: 350# 140 lbs. 61 ECT: 400 .

The corrugated box is one of the widely used testing instruments used in the packaging industry. Its quality matters the most in terms of holding the material for a longer time. . The bursting strength of the test specimen is expressed in terms of kg/cm2. You can easily make use of this testing instrument for different applications like .TAPPI T 807, Bursting strength of linerboard, Test Method [6] TAPPI T 810, Bursting strength of corrugated board, Test Method [7] TAPPI T 1200, Interlaboratory evaluation of test methods to determine TAPPI repeatability and reproducibility [8] Brauns O., Danielsson E., Jordansson L., Svensk Paperstidning 23 867 (1954) 1) [9]Additionally, the bursting strength of corrugated material is an international standard, meaning that it is essential for companies to meet this criterion in order to be competitive in the global market. . which indicates the strength of the paper/ corrugated cardboard/ carton box/ card board under test. This test is useful in quality control .

The simplified McKee formula above provides a quick estimate that should not be used to rate the strength of an actual box. Such an estimate shall not to be used in place of testing conditioned test samples in a controlled, repeatable test environment, with calibrated instrumentation, validated machines, and trained test operators. A: The Mullen Test measures the burst strength of corrugated board by determining how much pressure is required to puncture the face of corrugated material. In contrast, the ECT measures the edge compressive strength perpendicular to the direction of the flutes, which is crucial for understanding a box’s stacking strength.sizes and capabilities of corrugated boxes grew to fit the myriad of new products developed. Recently, the combination of a plastic bag inside a corrugated board box (bag-in-box) has resulted in many new opportunities, including the latest trend packaging of wine. Corrugated board is permeable to moisture and absorbs water. This will reduce its

Bursting strength is reported in pounds (for example, 275#). A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a measure of the edgewise compressive strength of corrugated board. It is measured by compressing .The bursting strength of corrugated boxes is defined as the ability of a material to withstand stress when subjected to external pressure. Thus, testing this property of corrugated boxes will let you determine their quality. The Mullen Test, also known as the Bursting Strength Test, determines how resistant the corrugated box walls are when .

The burst test determines the maximum resistance (in kPa) of a specimen to an increasing pressure. ZwickRoell burst testers determine the bursting strength of paper in accordance with ISO 2758.The bursting strength of board and .

determine the “strength” of a corrugated box as it relates to stacking, or Box Compression strength (also referred to as BCT or Box Compression Test strength). ECT is a more appropriate measure than Burst when stacking strength is a primary design crite-rion. Savings may be found for some packages by using lighter-weight components with .How to check easily the bursting strength of corrugated boxes with the use of a bursting strength tester for paper. +91 9210 903 903 . That's why it's so important to conduct a bursting strength test for corrugated boxes so that they can withstand the rigors of shipping. While there may be a slightly higher upfront cost, the added protection .Bursting Strength Tester price from Pacorr is competitively set, offering a high-quality solution designed to measure the bursting strength of materials like paper, cardboard, and corrugated boxes. This robust and precise instrument is essential for ensuring the durability and reliability of packaging materials.

corrugated bursting strength chart

Corrugated boxes are commonly used to package and ship products. While they are typically very strong and durable, it is important to test the bursting strength of the box to ensure that it can withstand the pressure of shipping. There are a few different ways to test the bursting strength of a corrugated box, but the most common is the Mullen .

To calculate the overall strength of the corrugated boxes and containers, There are several other values needed along with Bursting strength such as Edge Crush Test value and Ring Crush Test Value. Bursting Strength Calculation. The bursting strength of any material like fabrics, cardboards, paper or any similar material is very important to .A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free to bulge with the diaphragm. Hydraulic fluid is pumped at a constant rate, bulging the diaphragm until the test piece ruptures. The bursting strength of the test piece is the maximum value of the applied hydraulic pressure. 5 ApparatusThe Mullen Test measures the bursting strength of the corrugated linerboard while the Edge Crush Test measures linerboard stacking strength. The 200 lbs. Mullen box and the 32 ECT box are comparable in stacking strength. But that is where the similarity ends. . The strength of a corrugated box starts with its material. Learn more about PSI's .

To calculate the bursting strength of a corrugated box, you need to perform a standardized test using a bursting strength tester, also known as a Mullen tester. The process involves clamping a .

Historically, the long time industry standard has been the Bursting (Mullen) Test, which is related to the rough handling durability of corrugated material. Bursting. Test is a measure of the force required to rupture or puncture the face of corrugated board and is measured by a Mullen Tester. The Mullen Test measures the bursting strength of corrugated boxes. In other words, it tests the amount of pressure or force needed to rupture the wall of the box. Boxes that pass this standard are rated with the appropriate # or lb designation – 200#, 275#, etc. The Edge Crush measures the stacking strength of corrugated boxes or the amount .This test, also known as a Mullen Burst Test, is one of the most common material properties test required by carriers and governments. Bursting Strength testing basically measures the force required to puncture through a corrugated board. This strength comes from various factors, including the thickness of the paper liner layers, the narrowness of the flutes, and the layers of .The prime reason for the popularity of corrugated packings is its cost-effectiveness and light-weightiness. Despite being lightweight, it has very strong strength characteristics. A box manufacturer stamps the boxes with a certificate that describes the quality of the box. This description is printed after performing several tests on the box .

corrugated box strength guidelines

WEBNabrisa tranquila transando dando a buceta e se masturbando em videos porno. Privacy cantora Nabrisatranquila nua fodendo sua buceta e seu cuzinho.

bursting strength test of corrugated box|bursting strength calculator